Stonbury's journey to Net Zero carbon

Since enrolling in the Certified Emissions Measurement and Reduction Scheme (CEMARS) in 2019, Stonbury has been active in reducing carbon emissions and strives to do more.

The water industry is under pressure to slash its carbon footprint to meet the crucial 2030 Net Zero target. Stonbury understands that to achieve this vision, carbon reduction measures will be a major influencing factor in its choice of contractors and suppliers, and is pleased to play a leading role in helping clients to invest in a sustainable future.

Seeking lower-carbon solutions

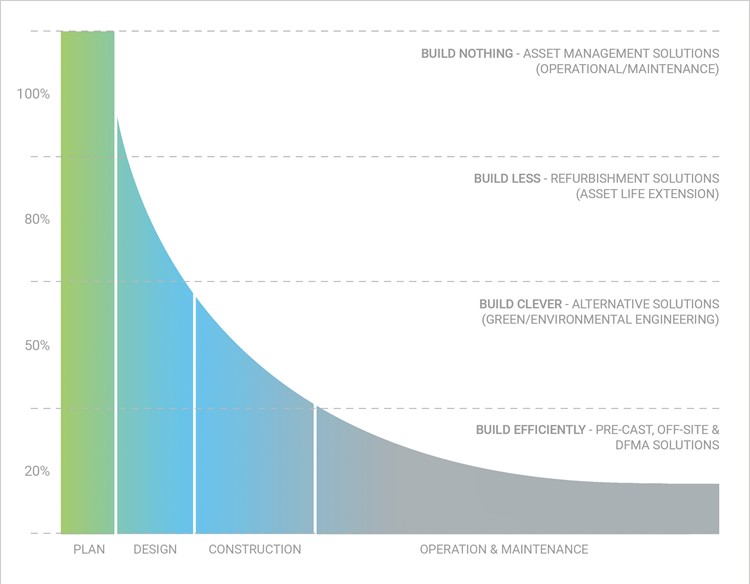

A key component in aligning Stonbury’s processes with the sector’s strategy to become carbon neutral is to identify the potential for carbon reduction within the stages of all projects. Guided by the Carbon Reduction Curve, Stonbury is able to work with clients from the design stage to explore alterative, lower-carbon solutions.

At the highest end of the curve, investing in natural capital and maintaining existing assets allows clients to Build Nothing and can reduce up to 100% of the carbon emissions associated with building new assets.

Building Less by refurbishing existing assets results in minimal construction and offers up to 80% carbon reduction when compared with a new build. As experts in refurbishment, Stonbury is proud to assist clients meet carbon targets by increasing the longevity of their assets.

‘Build Clever’ means employing out-of-the-box thinking to create green engineering solutions that utilise ecosystem services to treat water and protect its supply.

In the construction of new assets, Stonbury endeavours to Build Efficiently, minimising both embodied and operational carbon by embracing new technologies and materials, and when possible, offering clients these options at the time of tender.

Joining the dots: A whole system approach

Industry’s pledge to transition to Net Zero Carbon has led many companies to focus solely on CO2 reduction, but Stonbury understands the importance of practices that sustain natural capital and drive carbon reduction through the entire water cycle.

Stonbury’s work within the water environment sector enables the programming of nature-based solutions that result in Biodiversity Net Gain, helping clients utilise ecosystem services and significantly reduce the requirement for costly development and maintenance of traditional carbon-intensive asset interventions further down the catchment.

Stonbury is currently widening its profile in river restoration services and green engineering schemes, such as reed beds for tertiary wastewater treatment; a key area in which to reduce emissions. Such projects enhance biodiversity, protect against flooding and drought, and sequester carbon over time. Importantly, Stonbury recently began a move into green energy production, becoming involved in the construction of pioneering biomethane assets.

Phasing out carbon

Stonbury has made significant progress in minimising Scope 1 carbon; that is, direct emissions from in-house sources. After auditing revealed that oil and diesel represent the two largest contributors to its carbon footprint, Stonbury has made a commitment to phase out all petrol and diesel options from its managers’ and directors’ company vehicle catalogue.

On sites, reducing fuel usage is a priority. Current initiatives include the introduction of energy efficient eco-welfare units, battery powered tools and Hydrotreated Vegetable Oil fuel (HVO) for use in generators, which is being trialled for efficacy and cost on sites in January.

Although Scope 1 emissions continue to be phased out, Stonbury recognises that reducing emissions within the entire value chain is crucial to provide a truly carbon-neutral outcome. When working to Environment Agency Minimum Technical Requirements (MTRs), Stonbury reduces Scope 3 emissions by using re-cycled and locally sourced materials, and innovative products such as low-C cement, which can reduce the release of carbon by up to 70% compared with traditional mortars.

Though adoption of new technologies and products can be slow as engineers prefer tried and tested methods, Stonbury is a proud innovator and is continuing to trial and promote cutting-edge products and technologies in its journey to Net Zero. However, Stonbury recognises there is more to be done to reduce embodied carbon from within its supply chains and is committed to working with key suppliers and industry bodies to achieve its goals.

Embedding a sustainability culture

Stonbury’s designated department for Safety, Health, Environment, Wellbeing and Quality (SHWEQ) drives action on environmental policies, the progress from which is reviewed against long-term targets during monthly Carbon Strategy appraisals. The development of specific goals allows Stonbury to translate the climate challenge into achievable, measurable targets.

To meet carbon reduction goals, sustainability good practice should extend beyond environmental managers and into every area of the business. Therefore, Stonbury is working to engrain a green ethos into the commercial culture of the company, refreshing its Purpose, Vision and Goals to put sustainability at the top of the agenda and encourage buy-in from the entire workforce.

Embracing a new outlook

Sustainable options are commonly viewed as more costly, especially when new innovations are offered, but the cost of failing to protect vital natural resources is higher. In many cases, carbon is an effective metric for cost and resource efficiency; even within one project, choosing the ‘greener’ option can sometimes save thousands, for example in re-use of waste aggregates, or eliminating the need for generators.

At Stonbury, Net Zero Carbon is not just a target, but an encompassing passion; one which it hopes to inspire others to embrace. Turning the tide on traditional ‘grey box’ thinking, Stonbury aims to work collaboratively with both clients and suppliers to be a market leader in the delivery of lower-cost and lower-carbon engineering solutions.